FIRST STEP

DRAWING

Everything starts from a hand drawing, which, through a complicated study, is transformed into points and technical data to start the weaving

SECOND STEP

WEAVING

In this phase the yarn is transformed into fully-fashioned knit towels (front, back, and sleeves) already shaped. In the same time the finishes are also weaved, that is the edges, the collars and the cuffs.

THIRD STEP

LINKING STITCHING

The assembly of the different parts takes place through the "machine linking by hand". With this operation, which requires great manual precision, the knitters insert each point of the two component parts onto the machine needles by hand. These are then sewn together with one single thread, thus creating the precious "cucitura a catinella".

FOURTH STEP

WASHING

We use different types of washing, depending on the type of yarn and fineness, so as to give the sweater the desired appareance. To give to the sweater a soft appareance and a unique smoothness, the fulling is added to carded yarns.

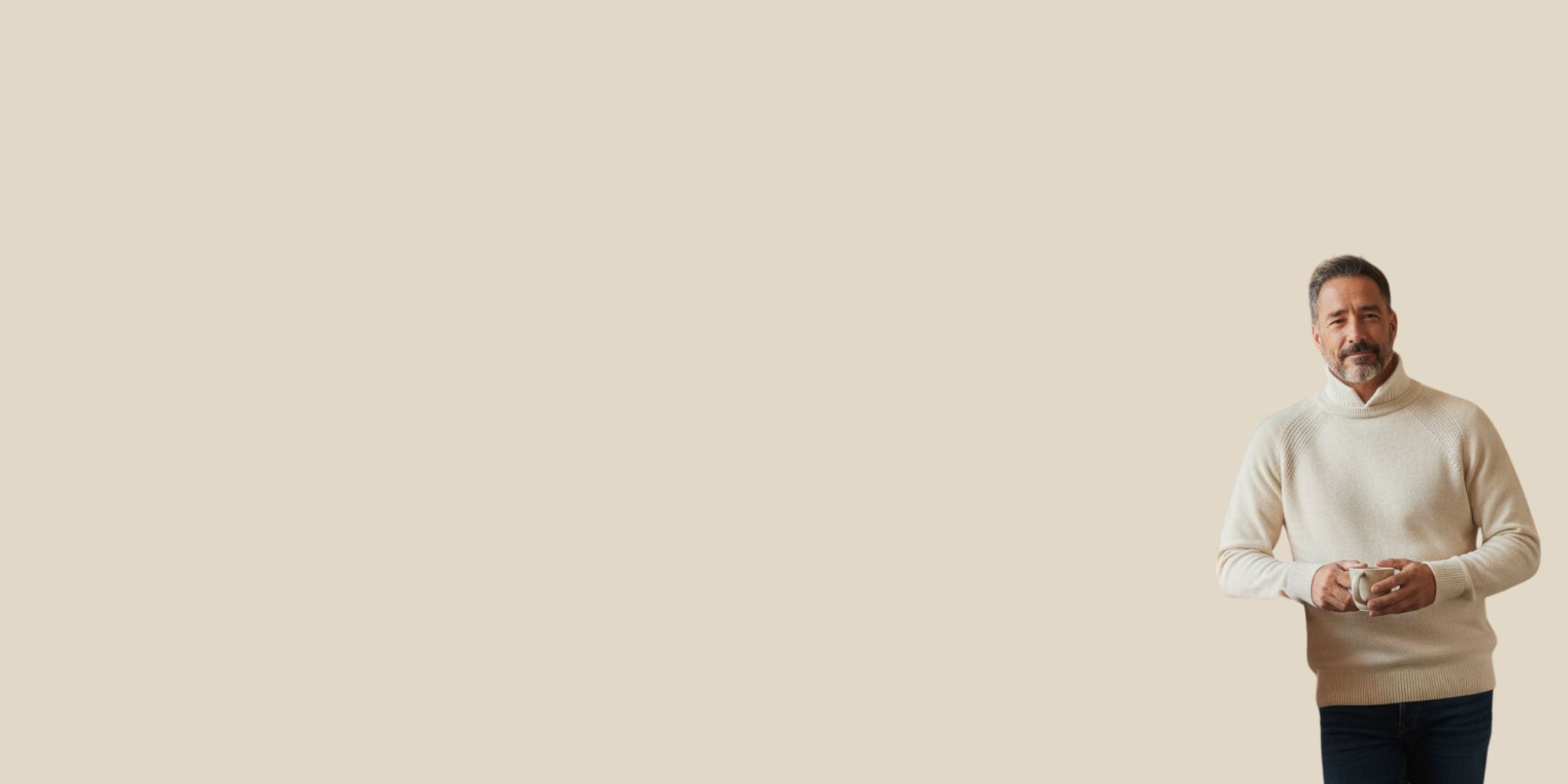

FIFTH STEP

CHECK

The finished garment undergoes a further check to detect weaving and tailoring defects, placing the sweater on a luminous mannequin.

SIXTH STEP

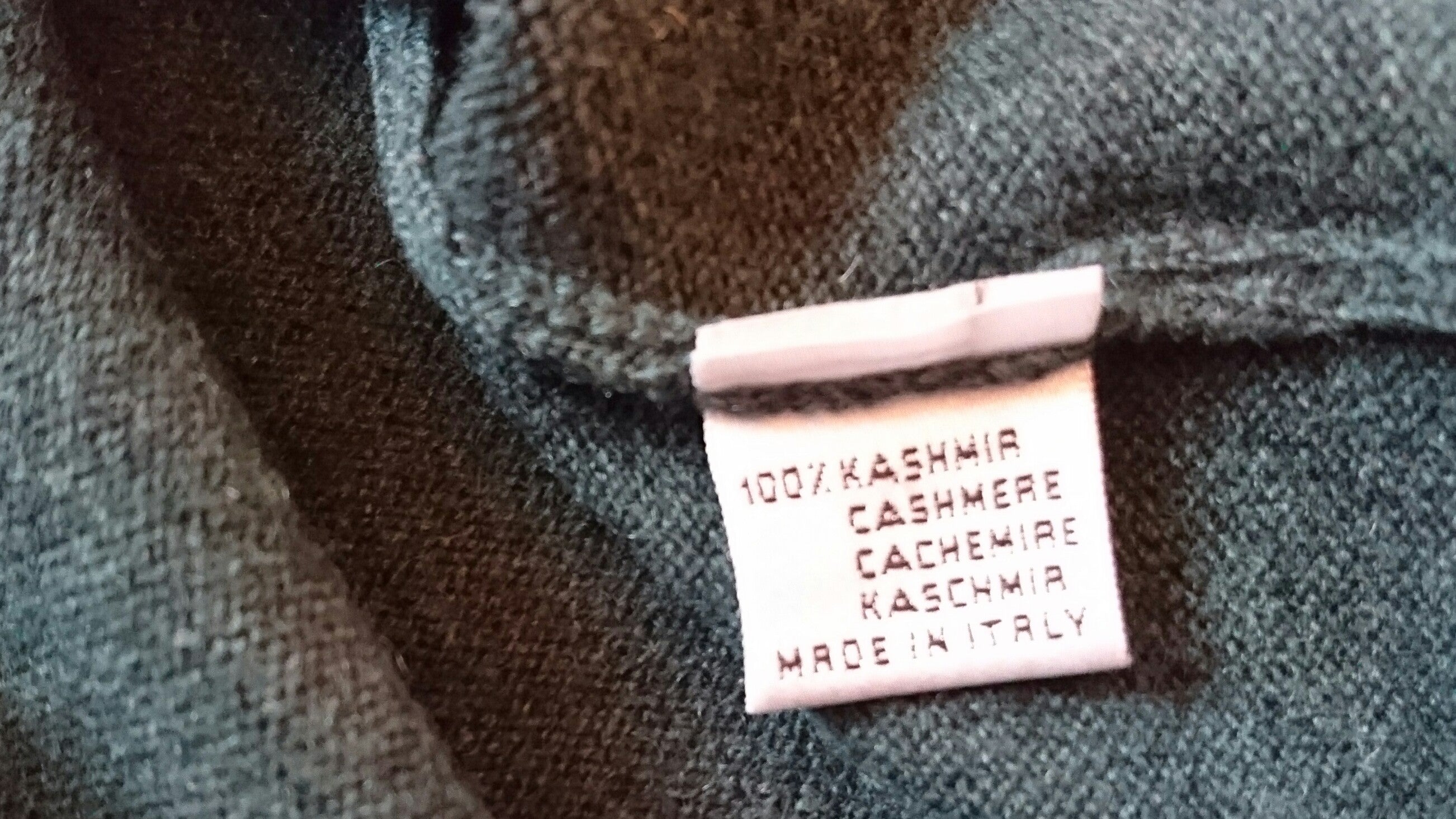

LABEL

Once quality control is passed, each label is hand-sewn.

SEVENTH STEP

IRONING

The last step is the ironing, which consists of an accurate and delicate steaming, and an adjustement by traditional iron.